Automatically derive quality predictions and optimal process conditions based on XGBoost and genetic algorithms

Vision x Validation

Industry domain-specific language model

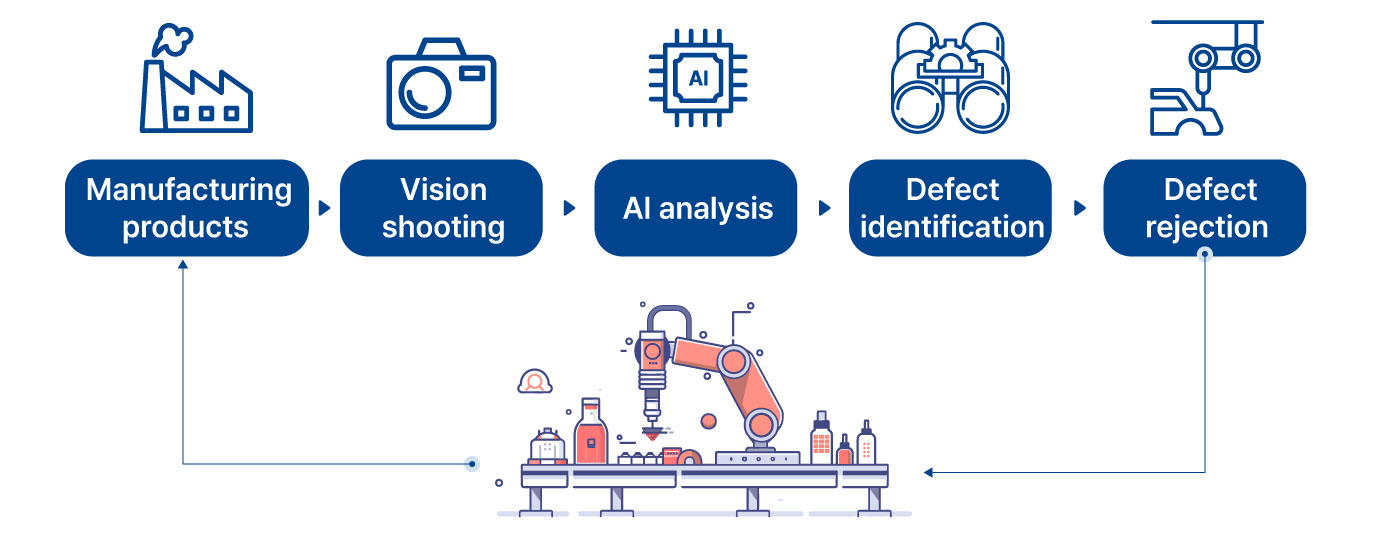

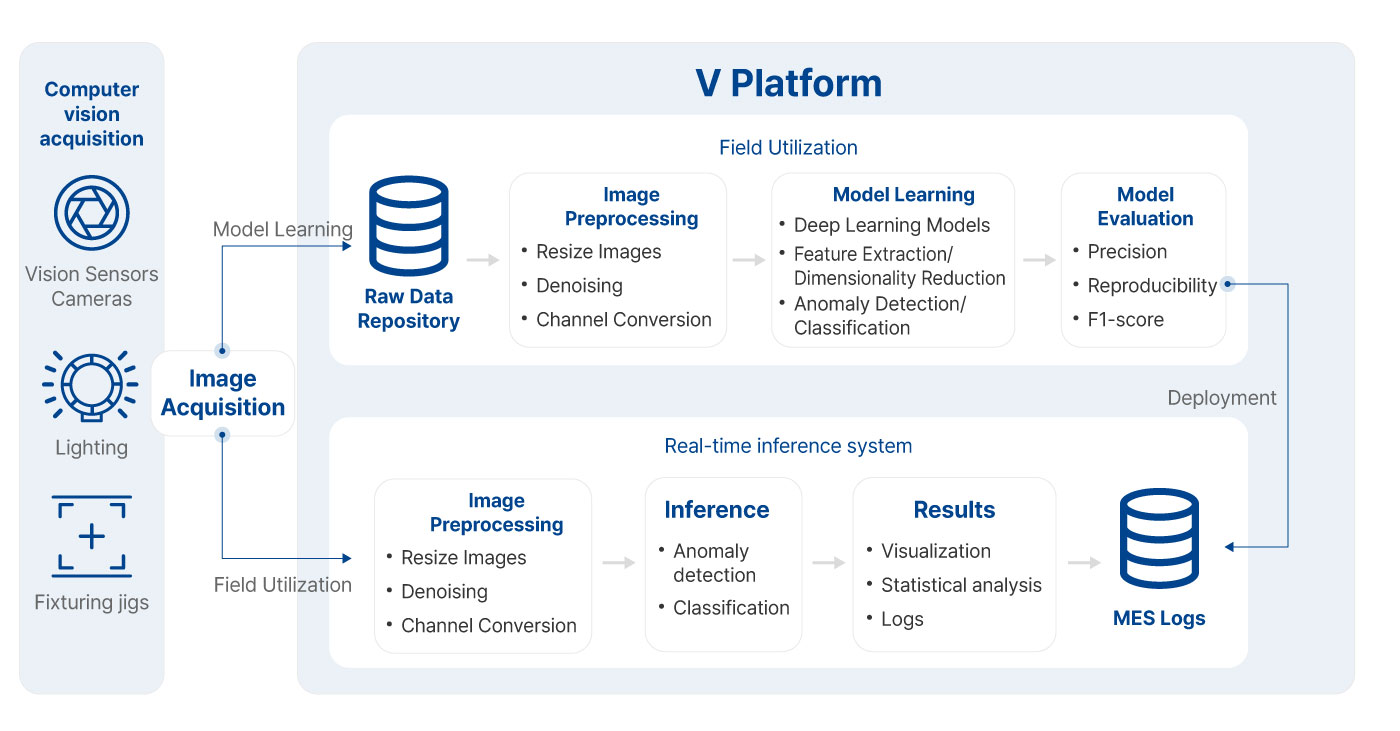

V² collects and analyzes images and process data from manufacturing sites in real time, and automatically detects micro-defects such as scratches and contamination based on AI deep learning.

By merging multimodal sensor data, quality can be predicted quantitatively, and high-speed inspection and derivation of optimal conditions are possible without interrupting the process using a lightweight model based on edge devices.

Automatically derive quality predictions and optimal process conditions based on XGBoost and genetic algorithms

Highly efficient vision anomaly detection with AI models based on normal images that can detect even subtle anomalies without learning

CNN-based deep learning algorithm automatically extracts quality and defect information from unstructured images and analyzes them precisely

Realize virtual sensors by analyzing data from various sensors and improve real-time judgment throughout the process

Real-time product

quality inspection

Quality prediction

and process

optimization analytics

Automate image

alignment and

quality inspection

Analyzing and visualizing

process characteristic

importance

Provide dashboard about

information summarized

on quality results

Suggest optimal

process conditions

Starting with the construction of a smart factory in 2019,

IMPIX has created best practices optimized for SMEs

through various AX(AI Transformation) projects.