The health functional food and cosmetics industry has high demands from consumers and certification organizations for food safety standards, quantitative formulation of chemical ingredients, and in-process hygiene/quality/traceability management. In order to improve the precision of raw material formulation and production hygiene management, AI autonomous control systems that can perform real-time analysis of formulation conditions and automatic control of environmental standards are required.

At the same time production history management, hygiene standard certification, history tracking for consumer quality satisfaction, recipe management, expertise in quality monitoring are required.

Required expertise: Recipe-based equipment operation and hygiene control, production history, expiration date, lot tracking management, integrated management of process hygiene and certifications such as HACCP and ISO

Pain Point

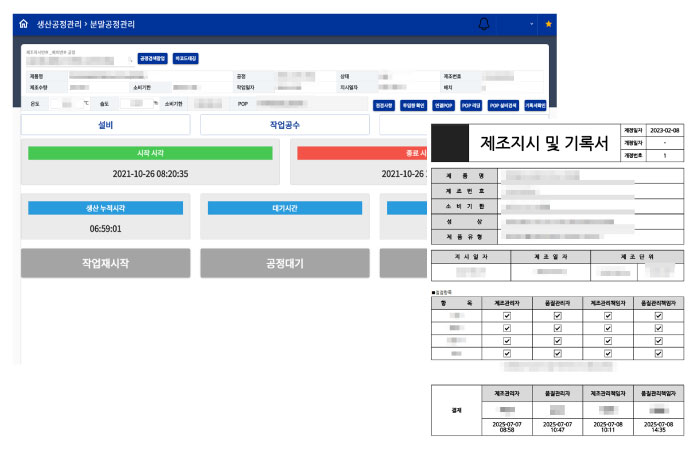

A manufacturing execution system that manages all production processes on the manufacturing floor

It is a manufacturing site system that focuses on real-time monitoring of manufacturing facilities, production management, status identification, and defect management.

It accurately records all production processes at the manufacturing site, from raw material input to process to product production, and provides optimized information to improve production efficiency.

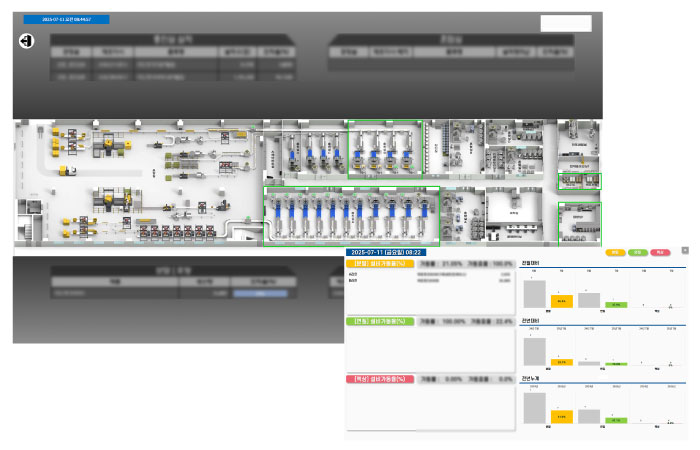

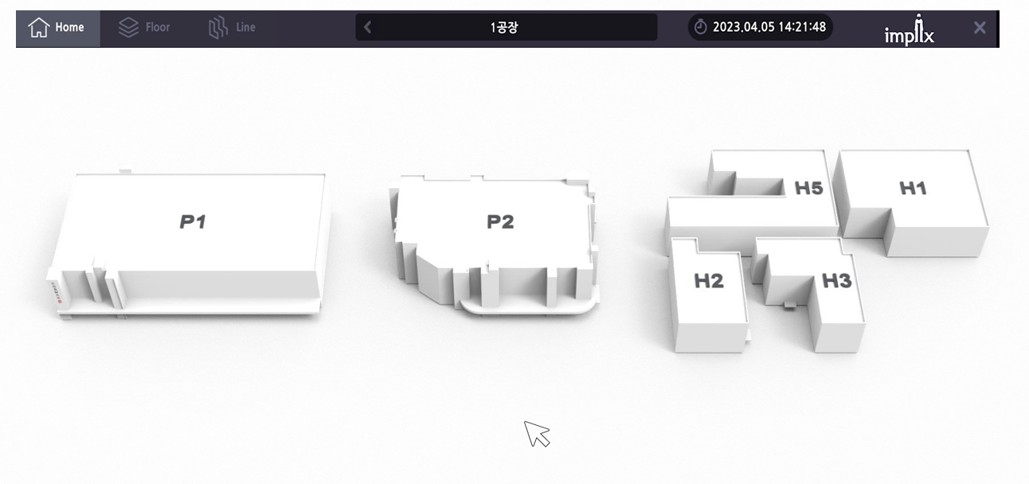

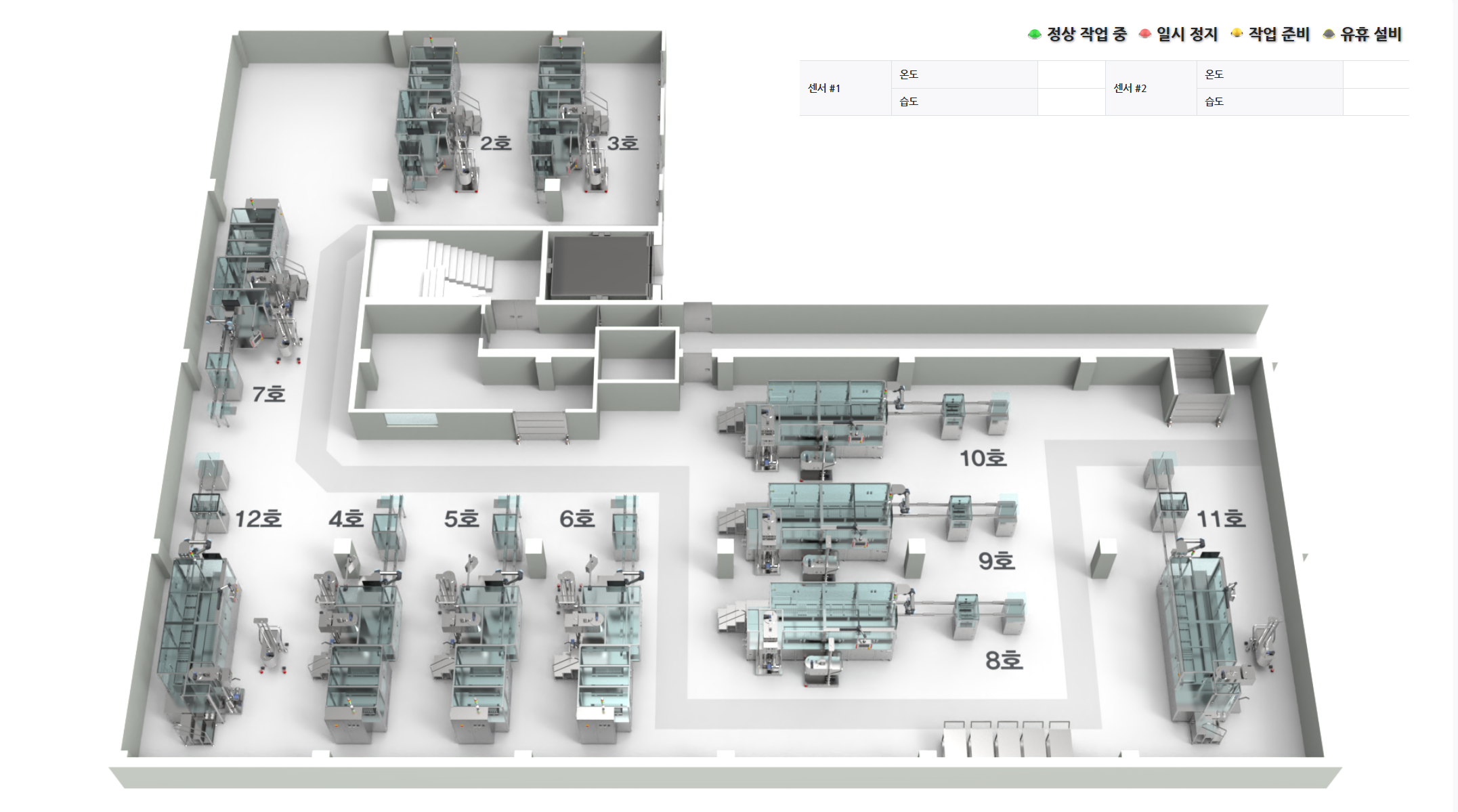

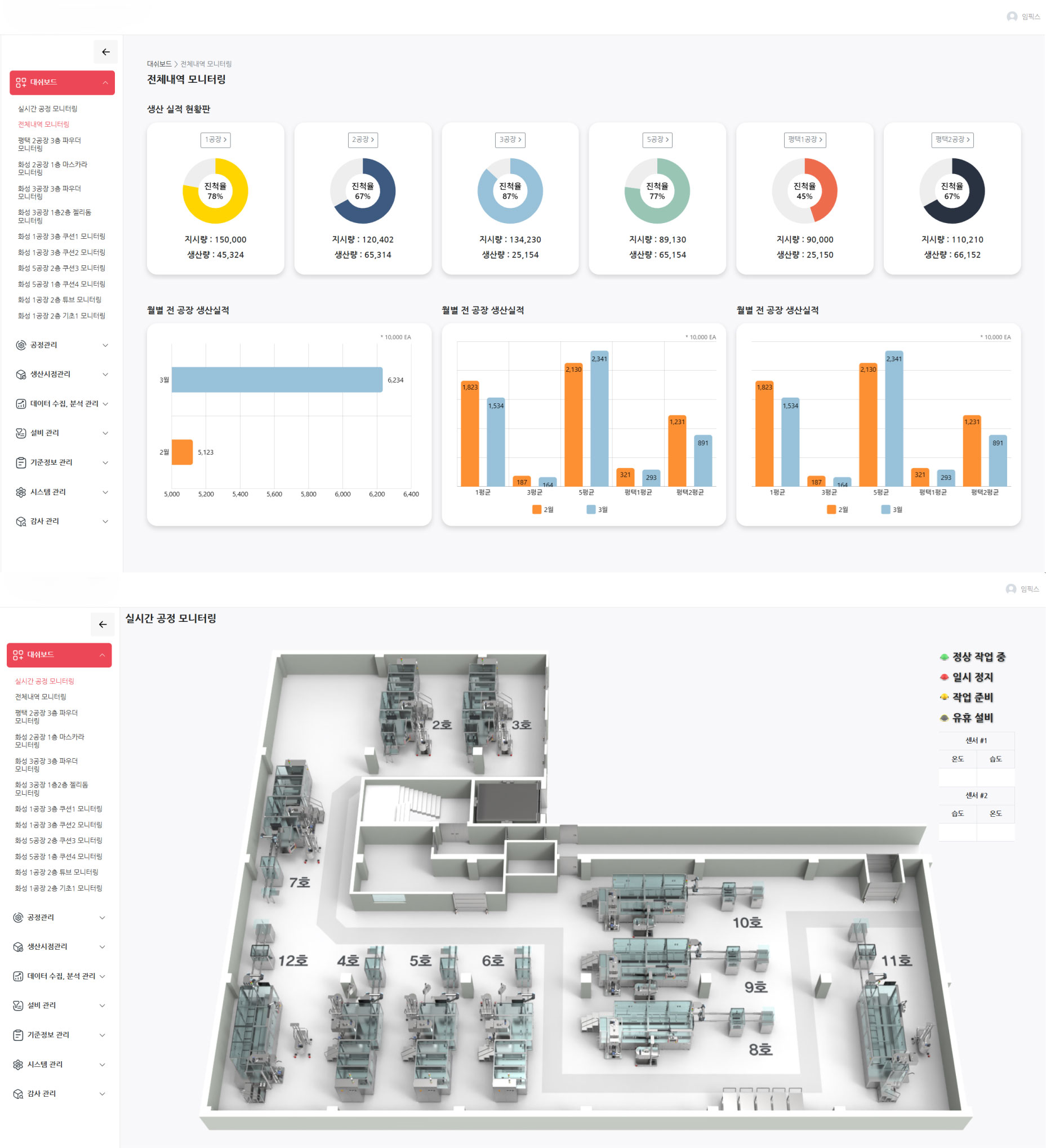

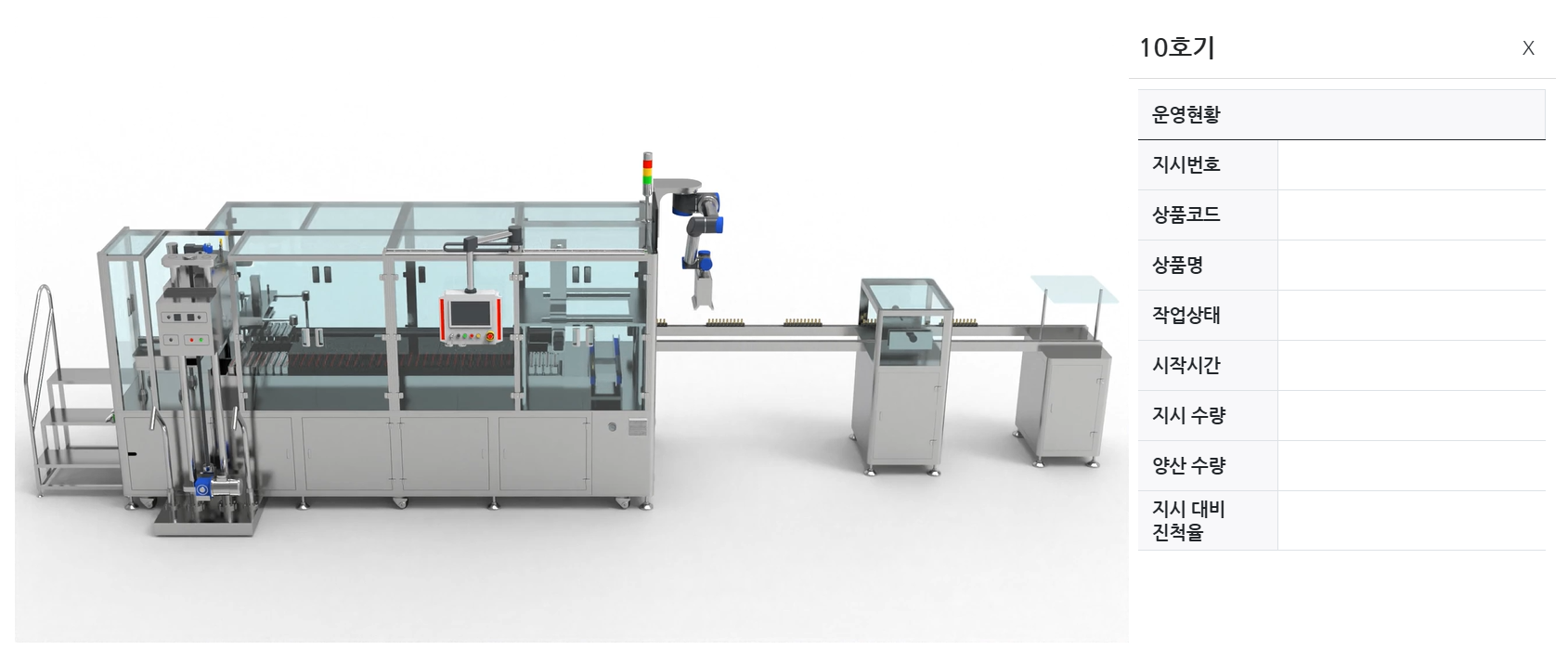

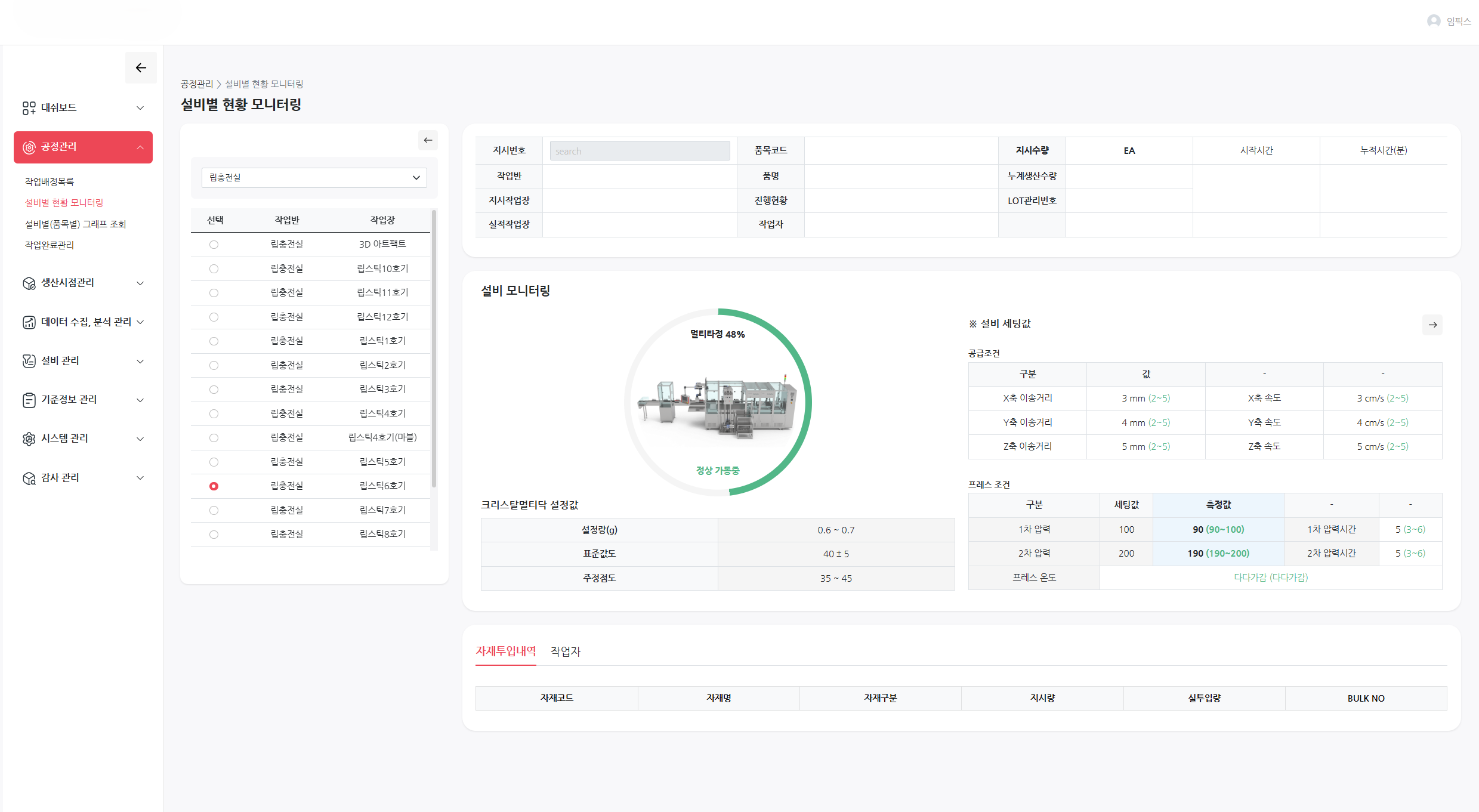

Real-time facility and production monitoring with 3D video and status boards

Intuitively monitor operational status across your processes with autoplay 3D video and status boards for each machine.

공정, 설비, 생산데이터의 자동 수집, 기록 및 관리를 통하여

자료의 신뢰성 및 활용성을 확보합니다.

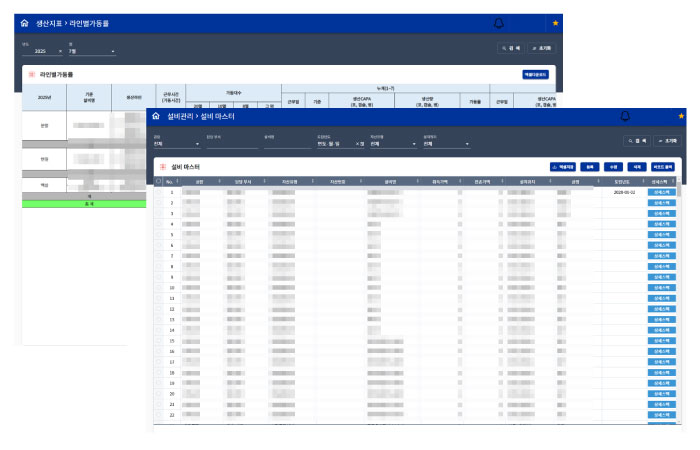

Integrated monitoring of pre-production processes and equipment lifecycle management

By establishing a process management system that can monitor and integrate the pre-production process in real time, we quantify the manpower, equipment status, and labor on the production line to support systematic productivity improvement and quality control..

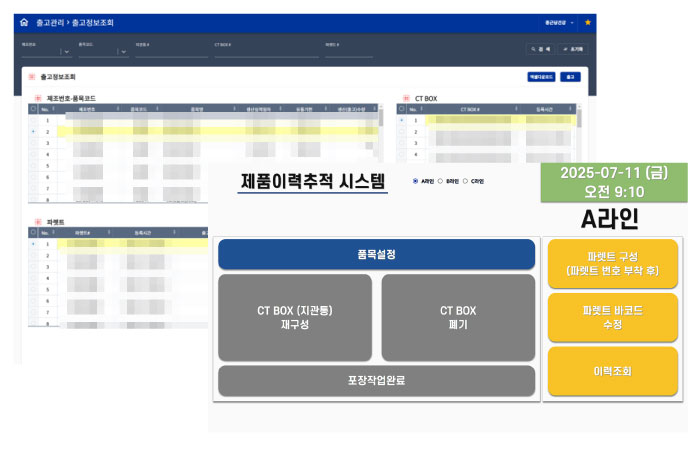

Manage all product LOT Tracking

Manage identities responsible for tracking and analyzing production LOT units, from the receipt of raw materials to the production of the products they go into.

Pain Point

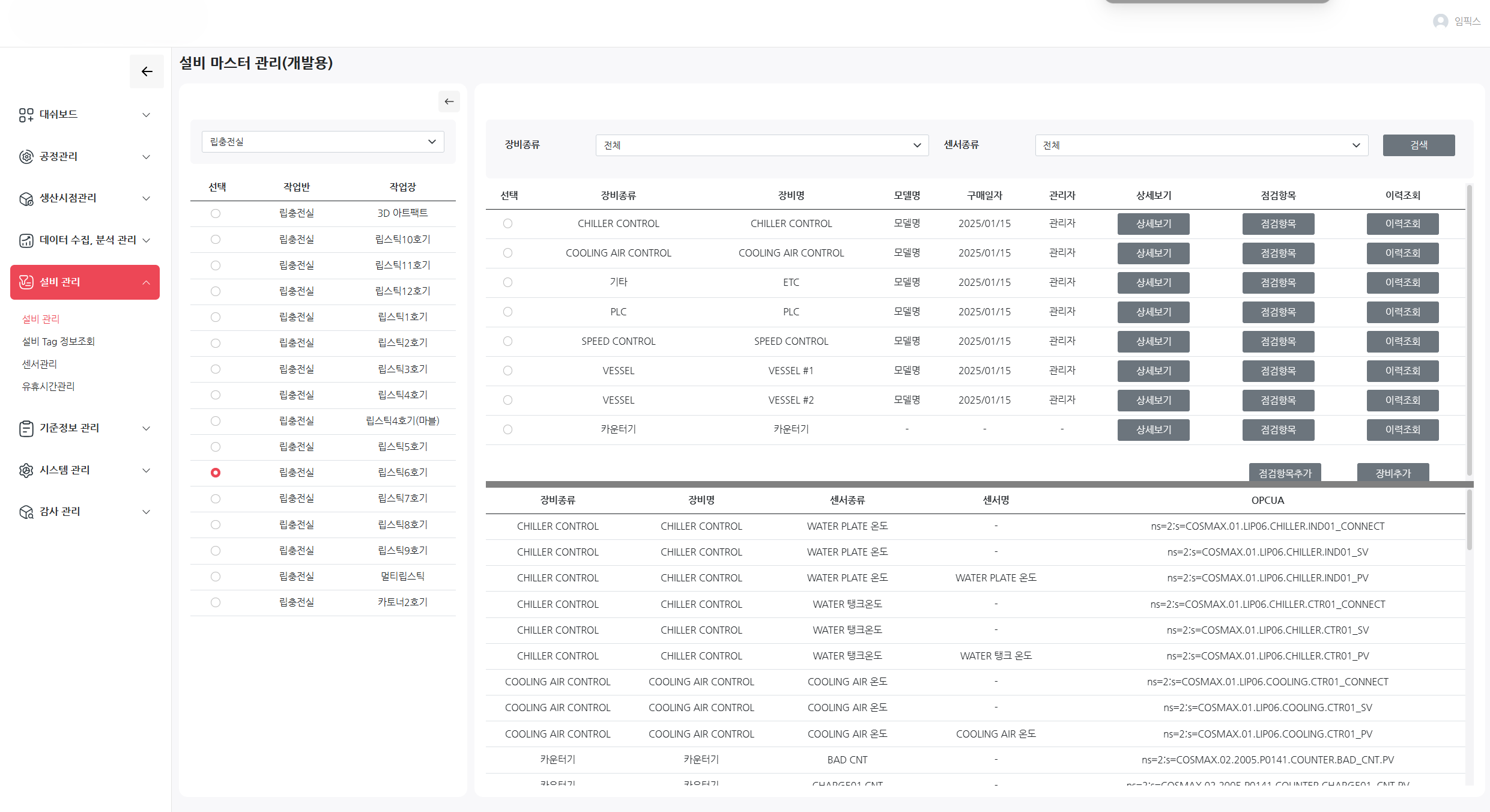

Management system from a production perspective through automatic input of equipment and process values

N-POP is a system that automatically collects and records various data generated on site based on production plans and work instructions.

Key information (performance, equipment operation status, production status by process) can be analyzed and viewed in real time, improving both operational efficiency and production quality.

Real-time facility and production monitoring with 3D imaging and status boards

Intuitively monitor operational status across your processes with autoplay 3D video and status boards for each machine.

Process management system based on early detection of equipment abnormalities and predictive maintenance

A facility diagnostic system is established to detect and manage facility abnormalities in advance by collecting facility operation information and quality data in real time. This will improve facility operating rates and ensure reliability based on predictive maintenance.

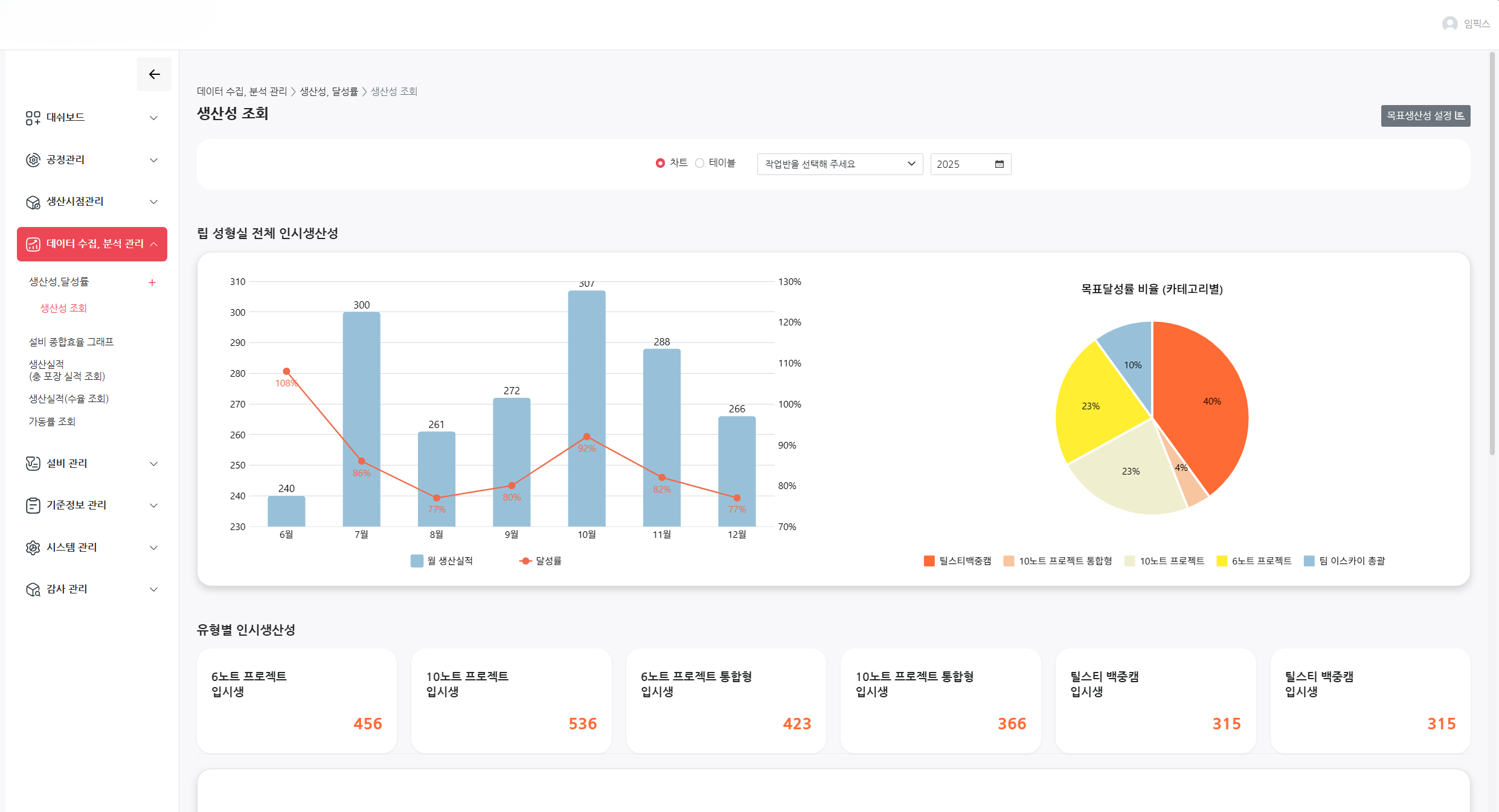

Visualization analysis function based on equipment-specific and process-specific data

It automatically collects various data from the field and provides real-time analysis results in tables and graphs to support efficient insight extraction.

Integrated monitoring of pre-production processes and equipment life cycle management

This is a process management system that enables real-time monitoring and integrated management of the entire production process. It supports systematic productivity improvement and quality control by quantifying the number of personnel on the packaging line, SOPs, and equipment status.

Starting with the construction of a smart factory in 2019,

IMPIX has created best practices optimized for SMEs

through various AX(AI Transformation) projects.