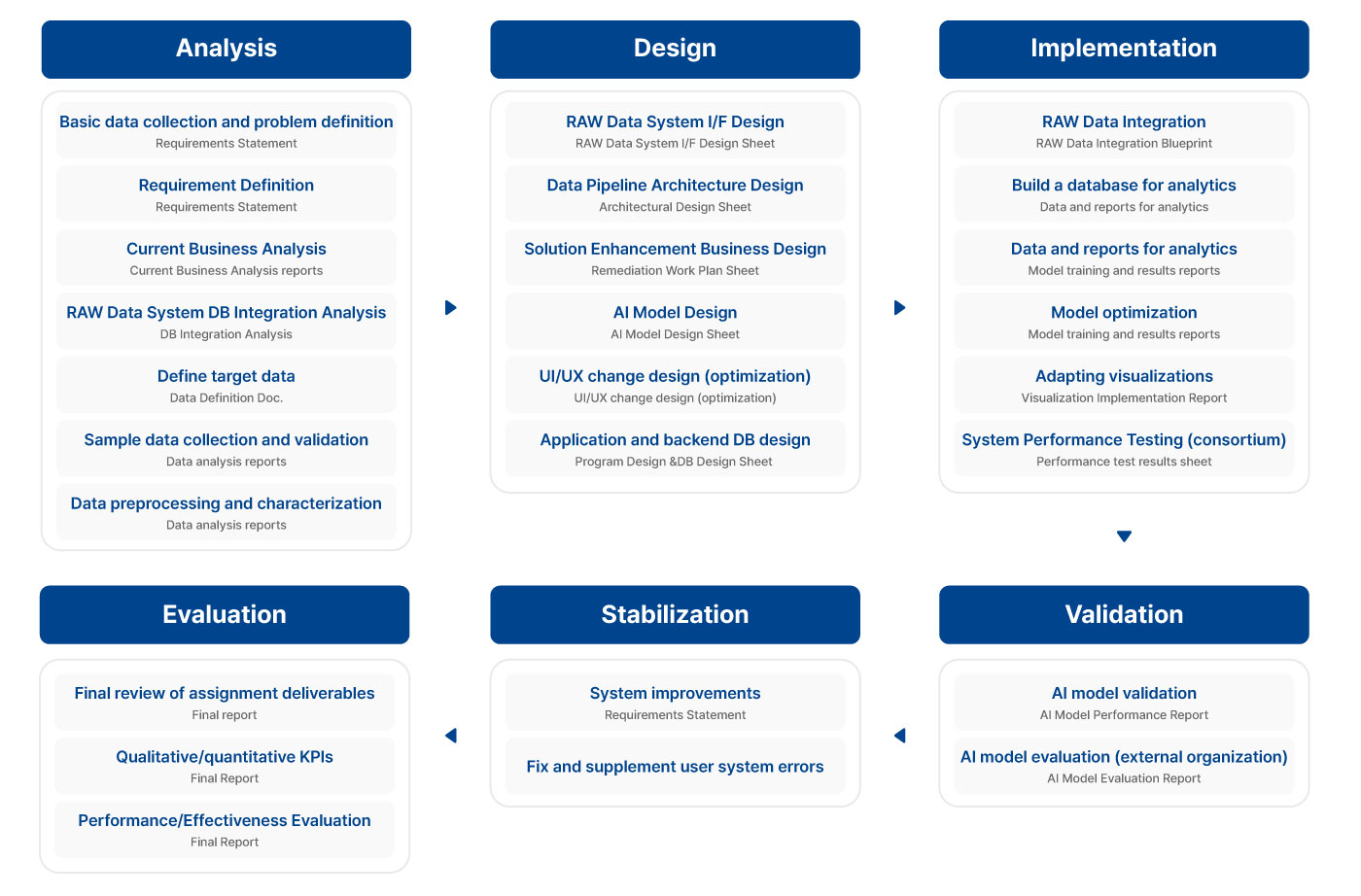

The automotive industry is characterized by multi-product assembly, simultaneous quality control of thousands of parts, and collaboration between processes.

For complex assembly processes and real-time judgment of part quality, an AI-based manufacturing collaboration system that can analyze data across processes and autonomously control facilities is required.

Digital twins, process scenario design, and AI-based quality determination capabilities are required to enable defect prediction, energy optimization, and production simulation.

Expertise required: Synchronized control between processes, part quality prediction, digital twin

Pain Point

Real-time facility data of key production processes is collected and reflected in a simulation environment to build a digital twin model that replicates the physical process on site.

This enables pre-verification and optimization of quality changes and potential anomalies based on operating conditions in a virtual space, and improves on-site response speed and accuracy by directly linking AI-based analysis and prediction results to visualized process models.

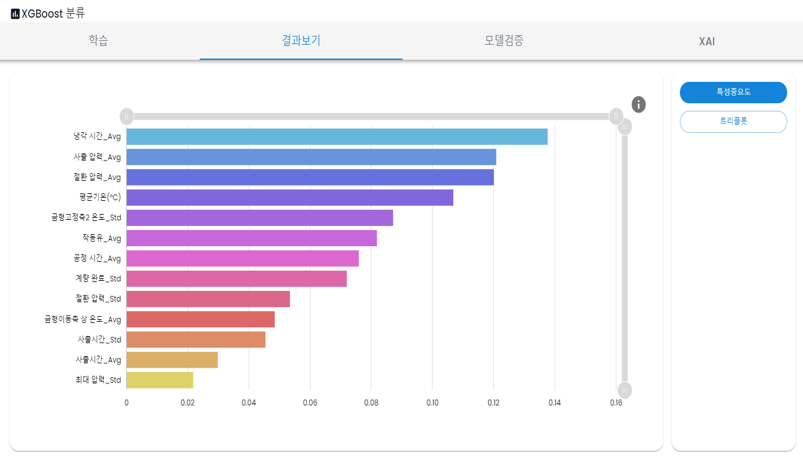

Analyze the correlation between process variables and quality outcomes based on collected dataset. AI algorithms identify key factors that influence the occurrence of defects, and visualize changes over time and cycles in an interpretable form based on XAI.

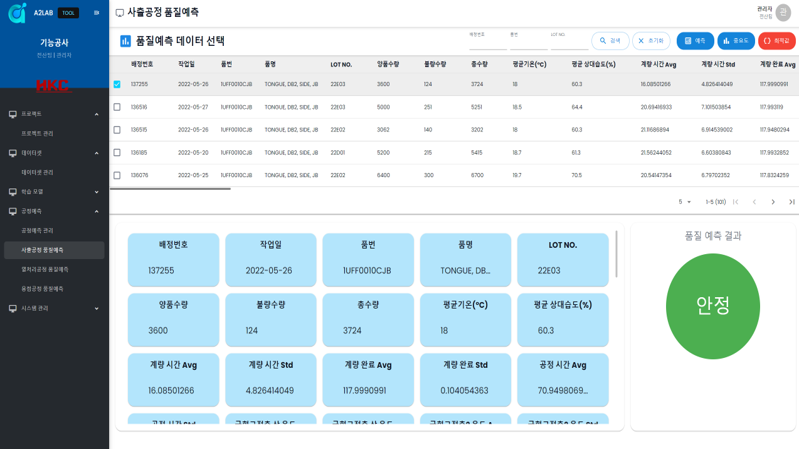

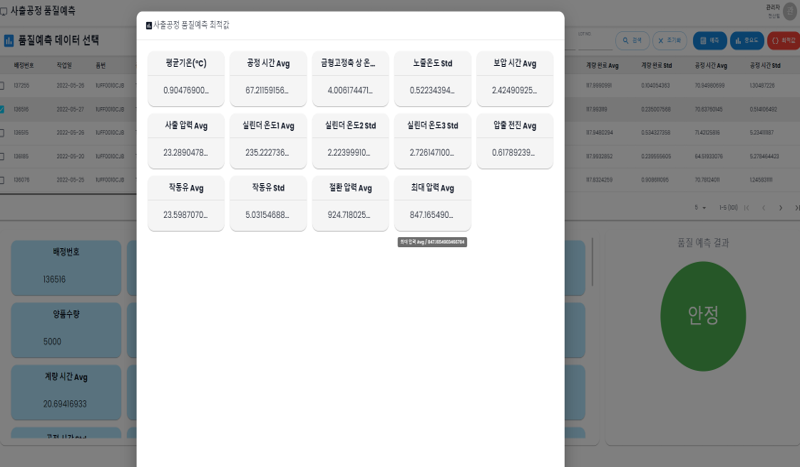

Proactively predict quality outcomes under different operating conditions with AI predictive models. It diagnoses the possibility of defects in advance and provides a warning system to reduce quality losses, contributing to increasing the quality rate and minimizing defect damages.

Automatically derive the optimal conditions for facility operation for each process based on AI analysis results. Based on this, operators can stabilize the quality of the molding, heat treatment, and welding processes and secure a sustainable high-quality production system.

We collect, store, analyze, and visualize equipment and process data from the field. This allows us to understand the distribution and characteristics of each process variable and establish a construction plan.

Starting with the construction of a smart factory in 2019,

IMPIX has created best practices optimized for SMEs

through various AX(AI Transformation) projects.